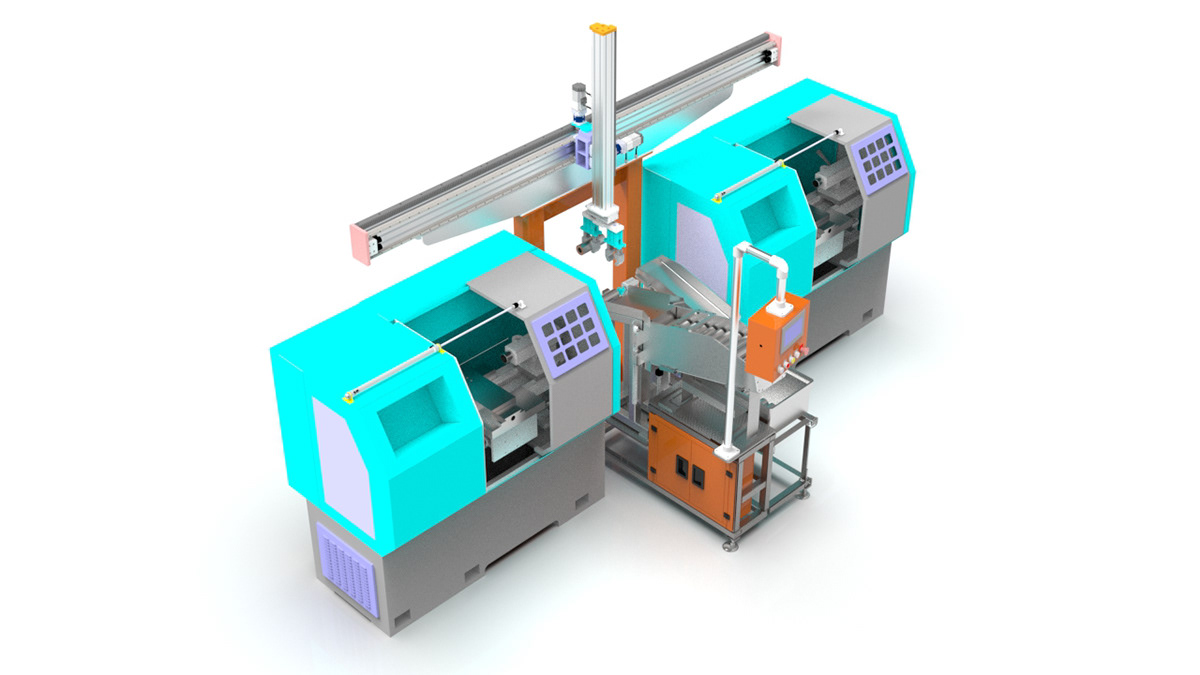

Automated CNC Lathe System with Robotic Arm 3D Design

The Automated CNC Lathe System with Robotic Arm is a cutting-edge solution designed to revolutionize the machining process. This state-of-the-art system combines the precision of two lathe machines with the versatility of a robotic arm, along with an automated material handling system for seamless operation. Developed using Solidworks, this three-dimensional model showcases the advanced features and capabilities of this innovative technology.

Description:

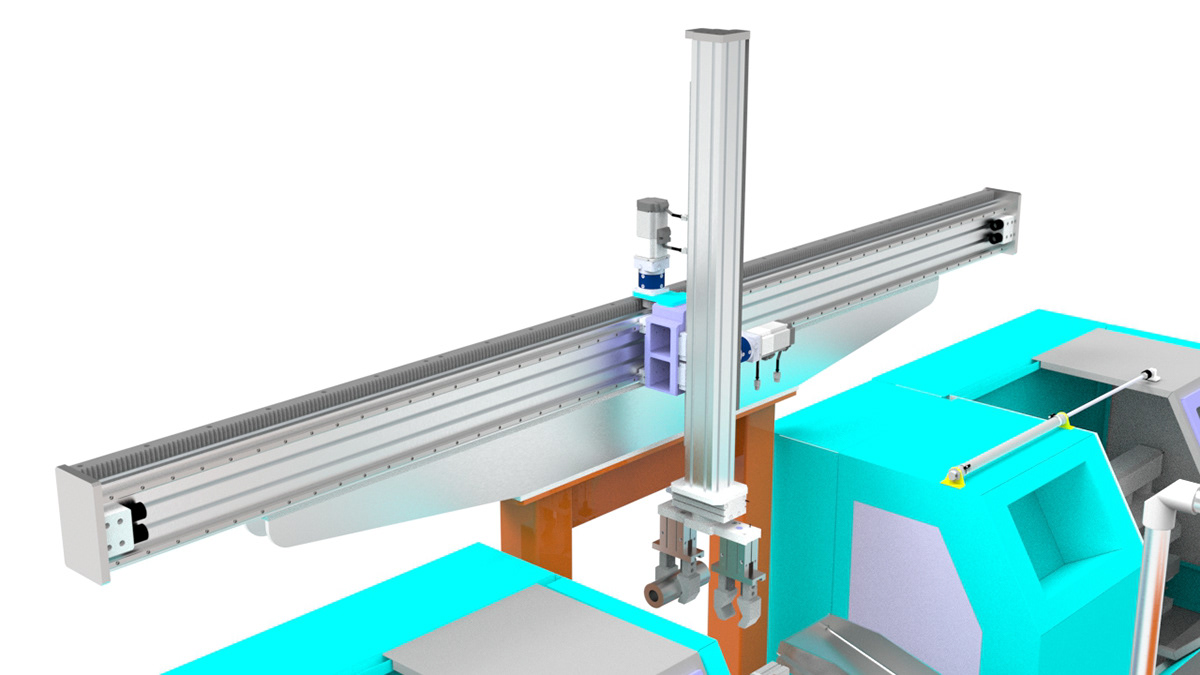

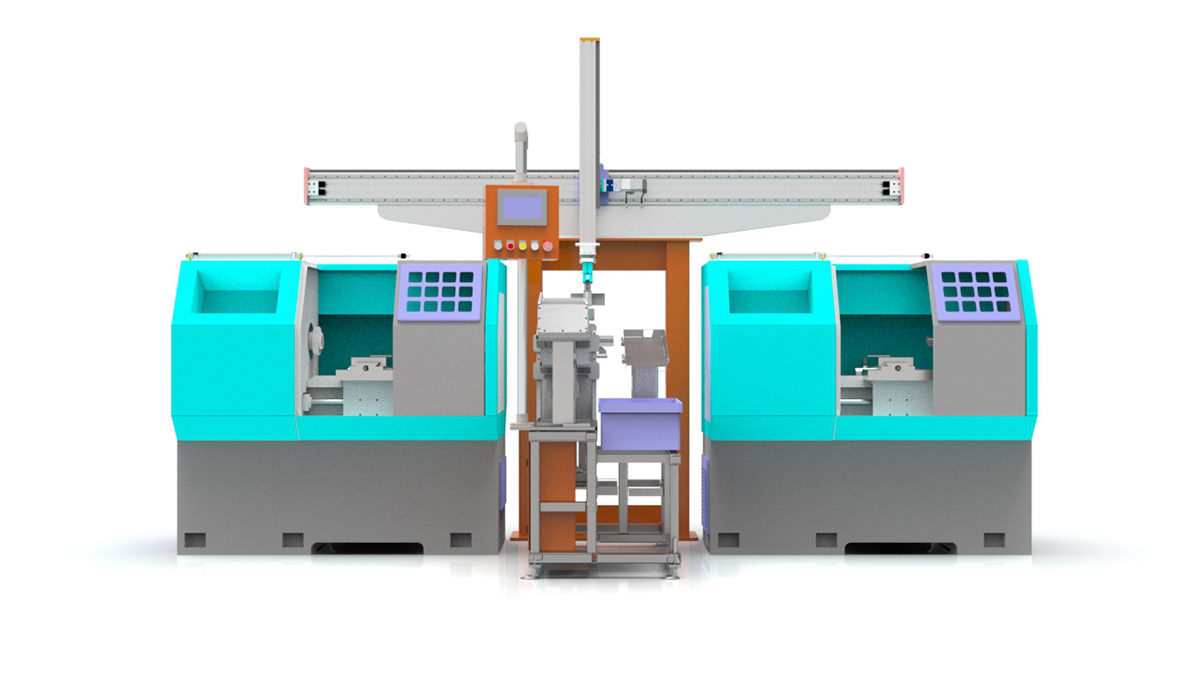

The Automated CNC Lathe System utilizes two high-performance lathe machines, strategically positioned with a robotic arm in the middle. This configuration allows for simultaneous machining operations, maximizing productivity and reducing manufacturing time. The robotic arm is equipped with a highly accurate gripper, capable of securely grasping and releasing workpieces with precision.

The system also incorporates an automated material handling system that streamlines the loading and unloading process. This system can automatically feed raw materials into the lathe machines and remove finished products, eliminating the need for manual intervention. It enhances efficiency and reduces human error, resulting in a smoother and faster production workflow.

The integration of the CNC technology ensures superior machining accuracy and consistency. The Solidworks model accurately represents the intricate mechanisms, including the precision components and intricate tool paths of the lathe machines. The user-friendly interface allows operators to program and monitor the system effortlessly, ensuring optimal machining parameters are achieved.

Key Features:

Dual lathe machines enable simultaneous machining operations for enhanced productivity.

Robotic arm with a precision gripper ensures secure and accurate workpiece handling.

Automated material handling system eliminates manual loading and unloading, reducing downtime and maximizing efficiency.

CNC technology guarantees high machining accuracy and consistency.

Intuitive user interface simplifies programming and monitoring for operators.

With the Automated CNC Lathe System, manufacturers can achieve unparalleled efficiency and precision in their machining operations. This cutting-edge technology minimizes production time, optimizes resource utilization, and enhances overall productivity, making it an invaluable asset for the manufacturing industry.

The Automated CNC Lathe System with Robotic Arm is a cutting-edge solution designed to revolutionize the machining process.